Rammax RX1575

MQ’s articulating trench roller is now more reliable than ever. The Rammax RX1575 is designed to meet contractor expectations for performance and durability. Loaded with all the features you need, the RX1575 articulates confidence.

- Flexible drum options include easy to remove drum rings that adjust from 33” to 24” working widths or 33” solid drums.

- Compaction performance and increased stability on uneven surfaces with a maintenance free oscillating articulation joint.

- Gain traction on tough material with steel padded drums and four scrapers.

- Increased control in all terrain conditions with a wireless remote transmitter covering a wider operational area & two ideally positioned receiver eyes.

- Charge the remote control battery with a solar panel or cable connector.

- Total safety concept reduces job site hazards. Visual contact is required between remote transmitter and receiver eyes, minimizing risk of accidents due to poor visibility. Roller automatically stops within 8 ft. (2.5m) of the operator.

- Reliable starting and performance with a powerful liquid cooled, 3 cylinder, Yanmar diesel engine.

- Able to withstand rugged work environments and steer quickly and precisely with two steering cylinders.

- Easy access to all maintenance points with fold-up front and rear covers.

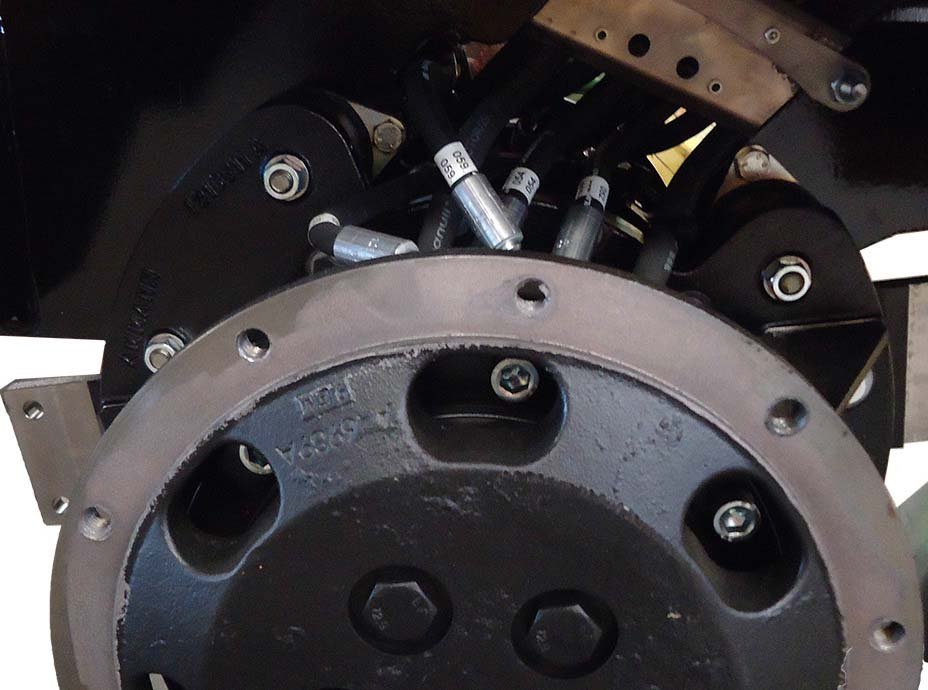

Unique oscillating:

articulation joint provides optimum traction and compaction on uneven surfaces. It also improves operational stability and reduces tip over risk.

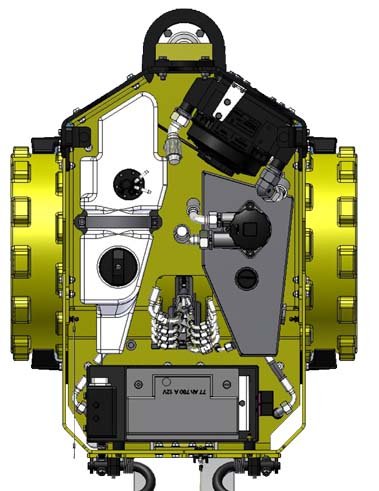

Hydraulic Hose Network:

Easily accessed through the drums with no special tools required. All hoses are routed to prevent wear and numbered for easy identification.

Frame Layout:

Convenient access to both compartments places battery, filters, oil fills, fluid drains and hydraulic hoses within reach reducing time spent on scheduled maintenance.

Exciter Design:

In maintenance free exciter shafts with oversized bearings and single cast construction to maximize service life.

A highly fuel efficient:

Yanmar engine idles automatically after 15 seconds of no load. Operating run-time can reach up to 11.5 hours with a 7.4 gallons diesel reservoir consuming only 0.74 gal/hr.

Infrared (IR) control:

System optimized for both operator safety and functionality. Requires visual contact with the machine for operation. Simplify fleet management by pairing transmitter to roller in seconds via cable connector. Blocks out signals from other machines on the job.

Ideally positioned:

IR receivers provide a wide operating range up to 66 feet at a 70 degree angle eliminating virtually any dead spot.